Additive Manufacturing for Structural Components in Superconducting Coils (MagAM)

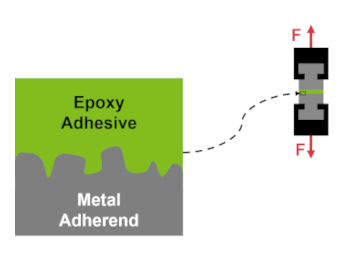

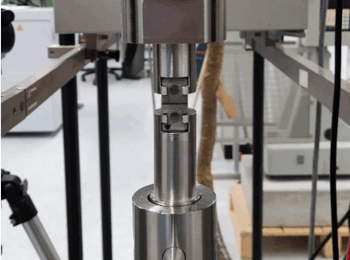

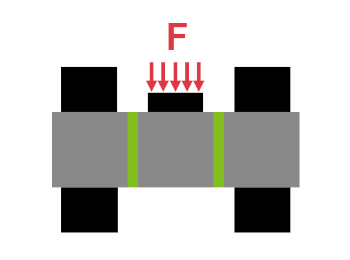

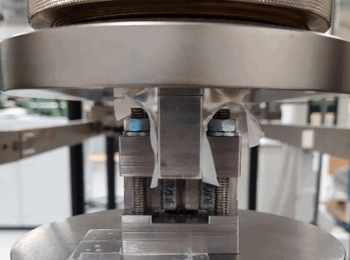

Nb3Sn-based coils of superconducting accelerator magnets are impregnated together with their structural components (wedges, endspacers, winding formers, etc.). The adhesion between the impregnated winding and the structural parts is a potential weak point, often linked to excessive training of Nb3Sn magnets. Additive manufacturing (AM) has the potential to produce very complex structures such as the winding formers of canted-cosine-theta coils (CCT), while adding enhanced functionality for increased adhesion, thus contributing to improved magnet performance. This project intends to bring these potential benefits into superconducting accelerator magnets.